|

|

|

|

| |

|

|

|

MANUFACTURING

At Chef John Folse & Company, we are committed to providing the exceptional service and quality products that our distinguished clientele have come to expect. Let us expand our wealth of experience into a successful business venture with you. Where success meets, great relationships grow.

The food manufacturing and sales division of Chef John Folse & Company was created in 1990 by Chef John Folse based on his vision of a changing food industry in America. From its humble beginnings, the manufacturing division has grown to national prominence with a customer base extending from the Gulf Coast to the Canadian borders and from the West Coast to the Eastern seaboard. The manufacturing of entrées, vegetables, soups, sauces and specialty products for foodservice distribution, retail sales and national restaurant chains forms the foundation of our organization.

Our USDA cook and chill manufacturing plant in Donaldsonville is capable of producing 150 tons of fully-cooked and ready-to-serve products weekly. From our state-of-the-art Chester Jenson kettles to our Cryovac On-Pack 2000 packaging system, our plant is designed to exceed USDA standards. Our Quality Assurance Department is our tool to ensure this.

Plant Floor

Our USDA manufacturing facility is capable of producing 50 million pounds of frozen or fresh, fully cooked and ready to serve product on a single shift per year. Our packaging capacity ranges from cryovac boil-in-the-bag to 55-gallon drums, as each customer's needs are different. Our minimum batch size for specialty product is 1000 pounds, or 62 (16-pound) cases. The following is a view of our plant cook floor, but it does not represent the total 32,000-square-foot facility. For more information on our equipment or capabilities, please feel free to call Chef John Folse & Company at 1-800-256-2433.

Casing & Packaging Information

NOTE: Since every customer's needs are different, our packaging size and pallet layout are designed specifically for each client.

| Gross Case Weight |

Net Case Weight |

Case Dimensions |

Case Cube |

Case Pack |

Pallet Pattern |

| 17.3 lbs. |

16.0 lbs. |

12 x 9 x5 1/4 |

.33 cubic ft. |

4-4 lb. bags/case

256 ounces/case |

128 cases/pallet

16 cases/layer

8 layers/pallet |

|

|

|

|

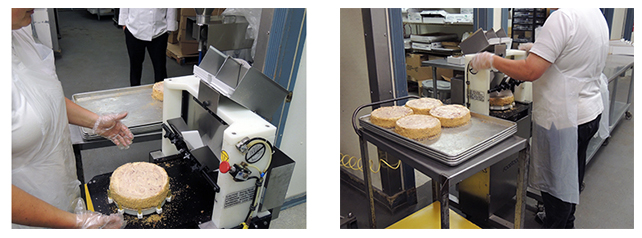

BAKERY

Chef John Folse & Company Custom Manufacturing fills a much-needed niche in the world of food product creation. Increasingly, foodservice, retail and chain outlets require a hands-on approach to food preparation, which is unable to be accomplished in mass production runs. Chef John Folse & Company’s Custom Manufacturing division has uniquely positioned itself to create these more labor intensive specialty food items with an emphasis on bakery and savory food products.

Examples of Custom-Manufactured Products

Breads

Muffuletta Loaves

Individual Ciabatta Breads

Custom-ingredient Hamburger Buns

Individual Sour Dough Steak House Loaves

Assorted Rolls

Sliced Table Bread

Desserts

Bread Pudding

Cinnamon Buns

Cakes (whole and sliced)

Creole Cream Cheese Cheesecakes (assorted varieties available)

King Cakes

Pound Cakes

Brownies

Dark Chocolate-coated Toffee

Roasted Pecan Toffee

Savory

Roasted, Stuffed and Breaded Mushrooms

Meat Pies (several varieties)

Meet Chef David Harris

As Director of Bakery Operations and Custom Manufacturing, Chef David Harris is responsible for the daily creation and delivery of fresh baked goods as well as development of customized manufactured bakery and savory items.

Before joining the ranks of Chef John Folse & Company in 1996, Harris served as Pastry Chef and Certified Working Pastry Chef for the Duquesne Club, one of America’s most elite business clubs. He has worked with several prominent foodservice facilities as well as four-star and four-diamond luxury hotels. In 1996, Harris was a member of the Culinary Olympic Team West and was awarded the silver medal at the world competition in Berlin. He brought home a gold medal for his role as advisor to the 2004 Regional Culinary Olympic Team. He has also received numerous awards and honors from various chapters of the American Culinary Federation including “Best of Show,” “Chef of the Year” and several gold medals.

Throughout his impressive career, Chef Harris has continued to pursue professional development at various institutions including the Culinary Institute of America, Balsam Grand Resort Hotel, Wilton School of Cake Decoration, National Guild of Baking and Pastry Professionals, The International School of Confectionary and the Dunwoody College of Technology where he studied Artisan Breads.

|

|

|

|